The packaging technology and demand for Ward wide electrode current detection resistance are interrelated. Packaging technology is a key link to ensure stable and reliable resistance performance, and demand is the driving force for the continuous progress of packaging technology.

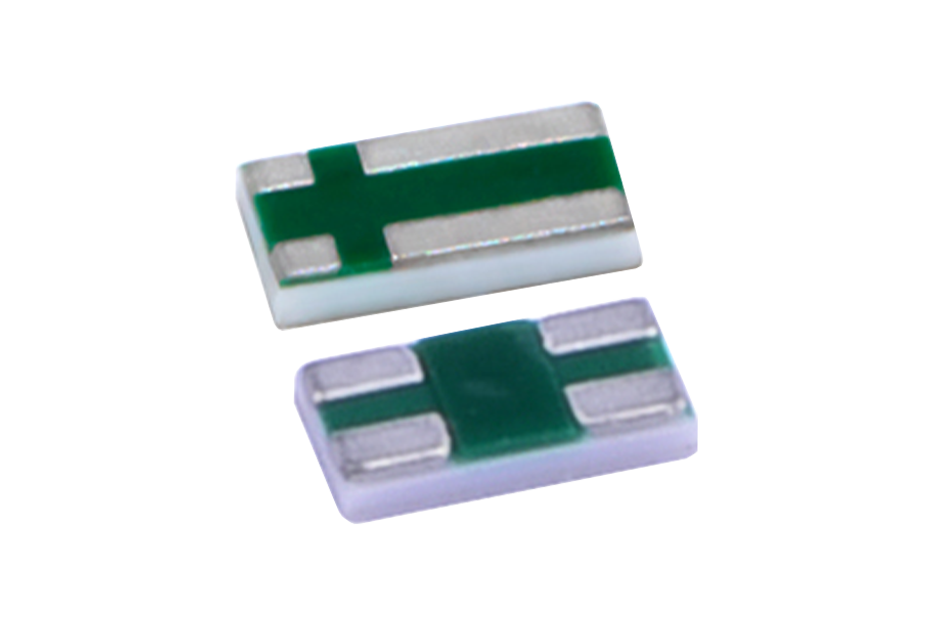

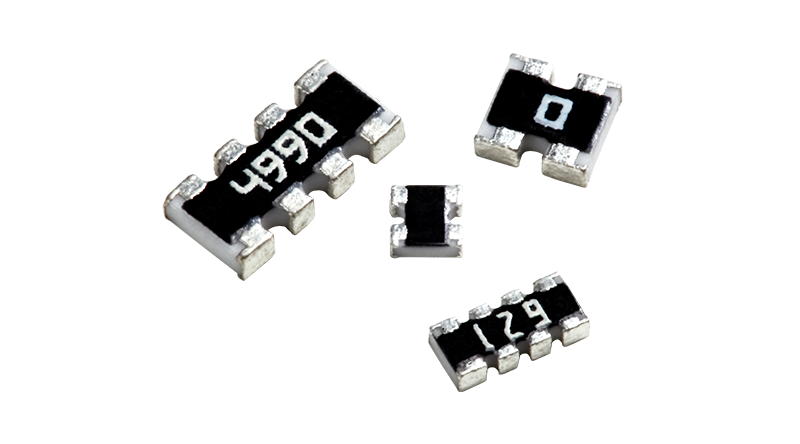

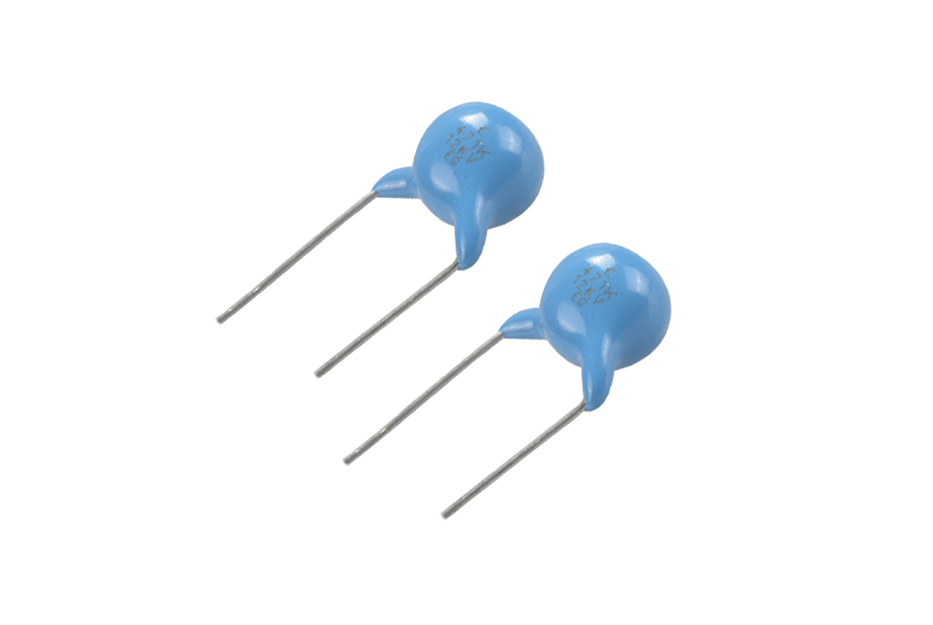

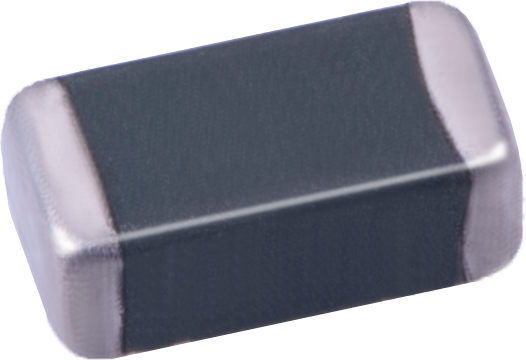

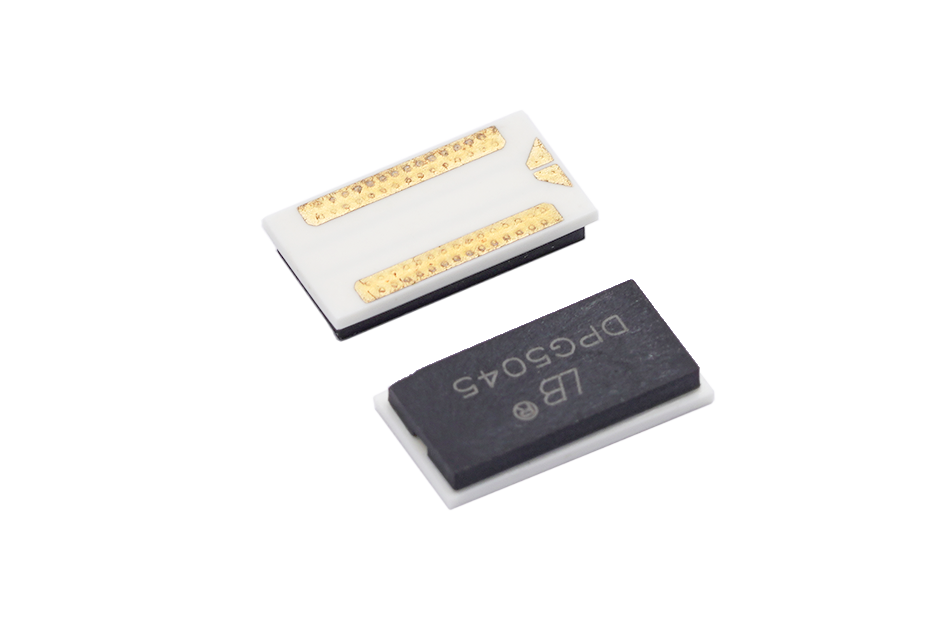

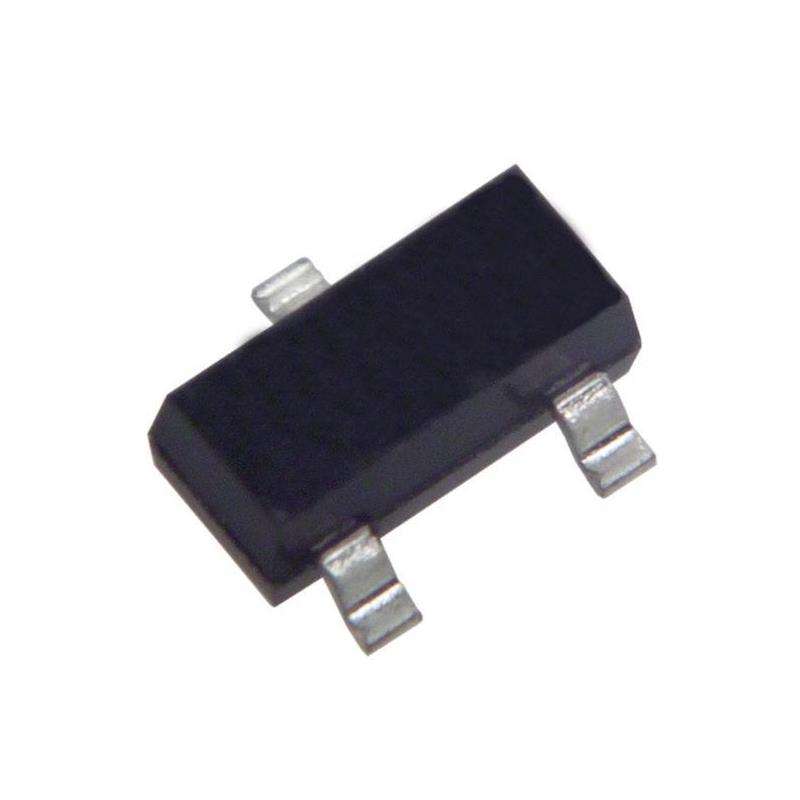

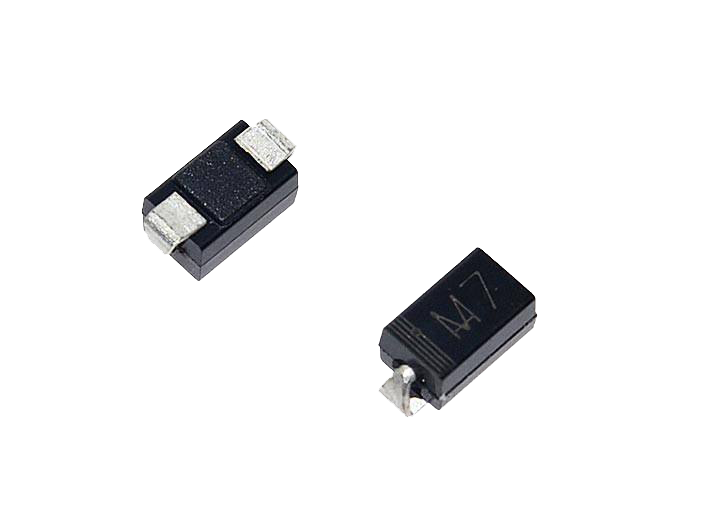

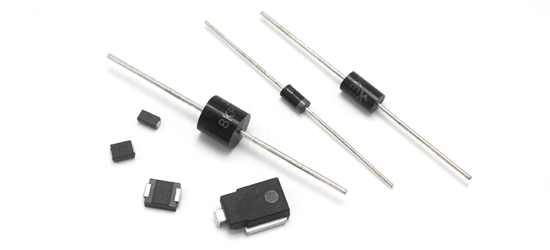

Packaging technology mainly involves pin design. The pin design of wide electrode current detection resistors needs to consider factors such as current flow direction, resistance value stability, and welding convenience. Reasonable pin design can ensure stable operation of resistors in harsh environments, while also facilitating welding and connection. There is also insulation protection, and the wide electrode current detection resistor needs to have good insulation performance to prevent current leakage and electric shock accidents. High quality insulation materials such as epoxy resin, ceramics, etc. are required during the packaging process to protect the resistance from external environmental influences. There is also thermal design. The wide electrode current detection resistor generates heat during operation. If the heat is not properly controlled, it may affect the stability of the resistor. During the packaging process, thermal design needs to be considered and appropriate heat dissipation measures such as heat sinks and holes should be taken to reduce the working temperature of the resistor.

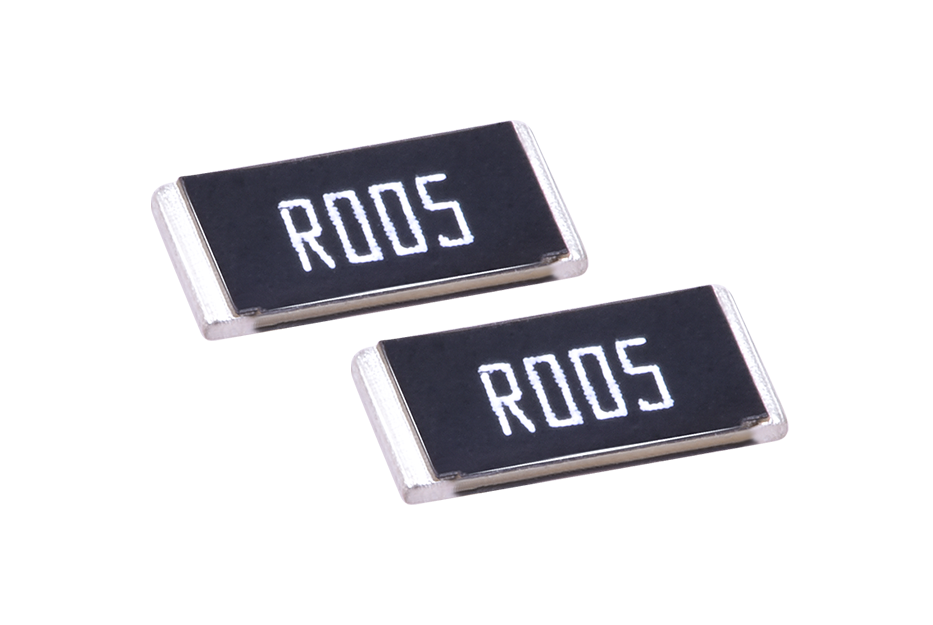

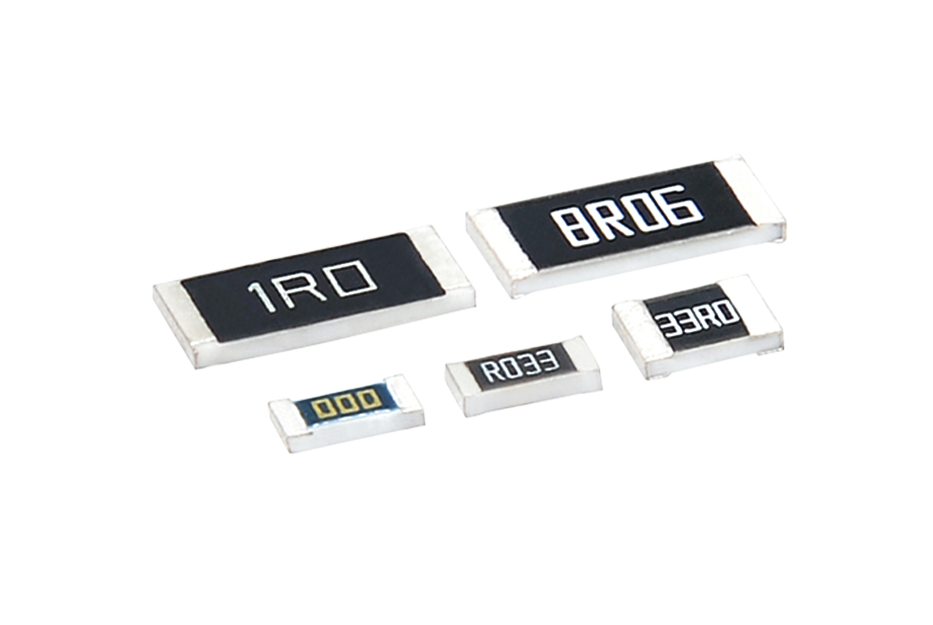

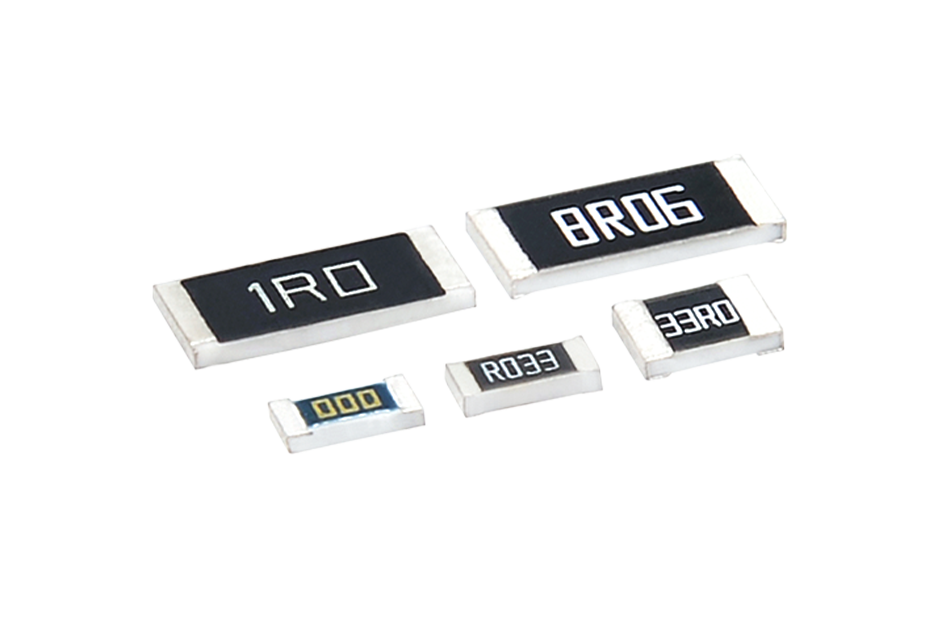

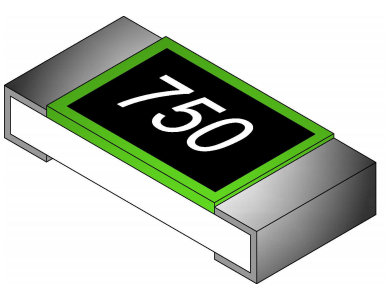

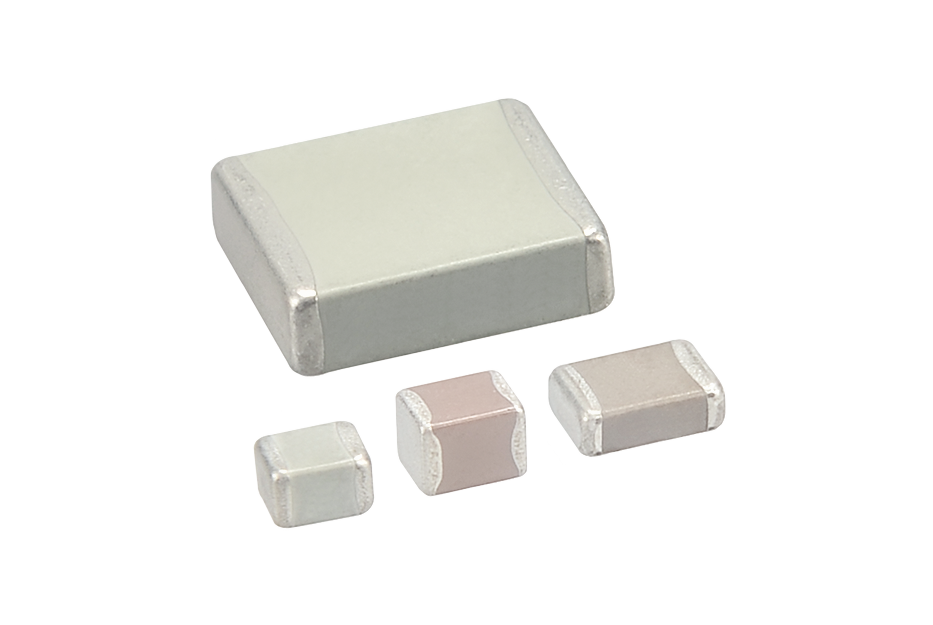

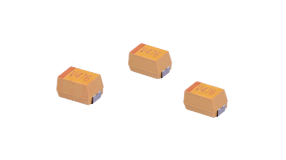

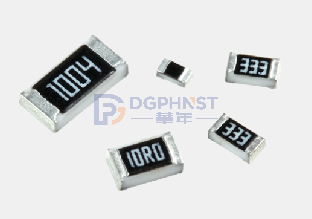

The main requirement for detecting resistance with Ward wide electrode current is that the resistance has high precision and can accurately measure the current value. High precision manufacturing processes and materials are required during the packaging process to ensure the accuracy and consistency of the resistance. There is also stability, which can adapt to various harsh working environments. High quality materials and manufacturing processes are required during the packaging process to enhance the stability and reliability of the resistor. The appearance is small, and with the continuous miniaturization of electronic devices, the wide electrode current detection resistor also needs to have the characteristics of miniaturization. During the packaging process, compact design and manufacturing processes need to be adopted to reduce the volume and weight of the resistor. Another thing is that the packaging process is simple, and easy to solder and design manufacturing processes should be used during the packaging process. User installation is simple and convenient to use.