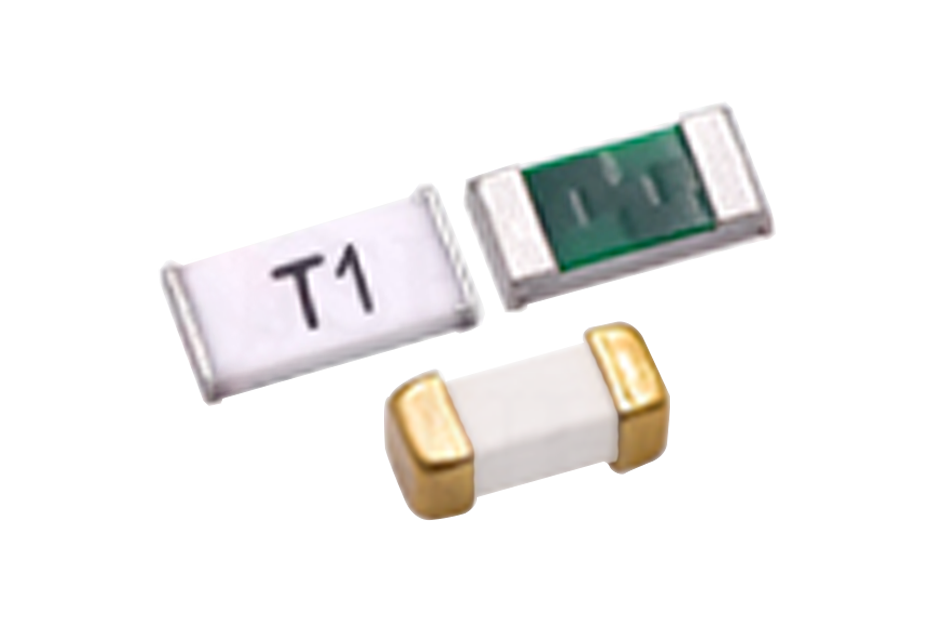

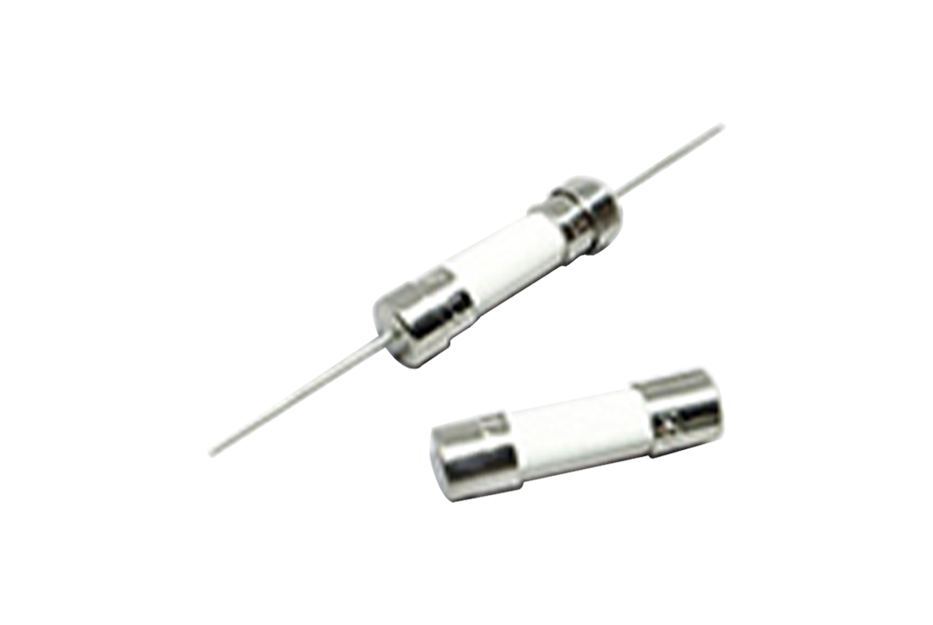

This paper will focus on the selection of XC ELECTRONICS 4T/5T glass tube slow fuse, XC ELECTRONICS 4T/5T glass tube slow fuse as a common protection element, the selection is very important to ensure the stable operation of the equipment.

Basic parameters of XC ELECTRONICS glass tube fuse

The main parameters of 4T/5T glass tube slow fuse include rated current, breaking capacity, working temperature and welding conditions. Among them, the rated current is the maximum current value that the fuse can withstand for a long time; Breaking capacity refers to the maximum short-circuit current that the fuse can be safely cut off under specified conditions; The operating temperature refers to the temperature range of the fuse in normal operation; The welding condition is related to the reliability of the fuse in the installation process.

For the XC ELECTRONICS 4T/5T glass tube slow fuse, its breaking capacity reaches 35A, which means that when the short circuit current reaches 35A, the fuse can be quickly blown to cut off the circuit, thereby protecting the equipment from damage. At the same time, its operating temperature range is -40 ° C to +125 ° C, which makes it able to work normally under extreme ambient temperatures. In addition, the requirements of welding conditions r:260 ° C ≤5S, 360 ° C ≤1S also ensure the stability and reliability of the fuse during installation.

XC ELECTRONICS glass tube fuse selection

In the selection, we must first consider the actual working current of the equipment. In general, the rated current of the fuse should be slightly greater than the actual working current of the device to ensure that the fuse will not misoperate when the device is working normally. At the same time, we also need to consider the short-circuit current of the device. If the short-circuit current of the device exceeds the breaking capacity of the fuse, the fuse may not be able to blow quickly during a short circuit, resulting in damage to the device. Therefore, we need to choose a fuse with sufficient breaking capacity.

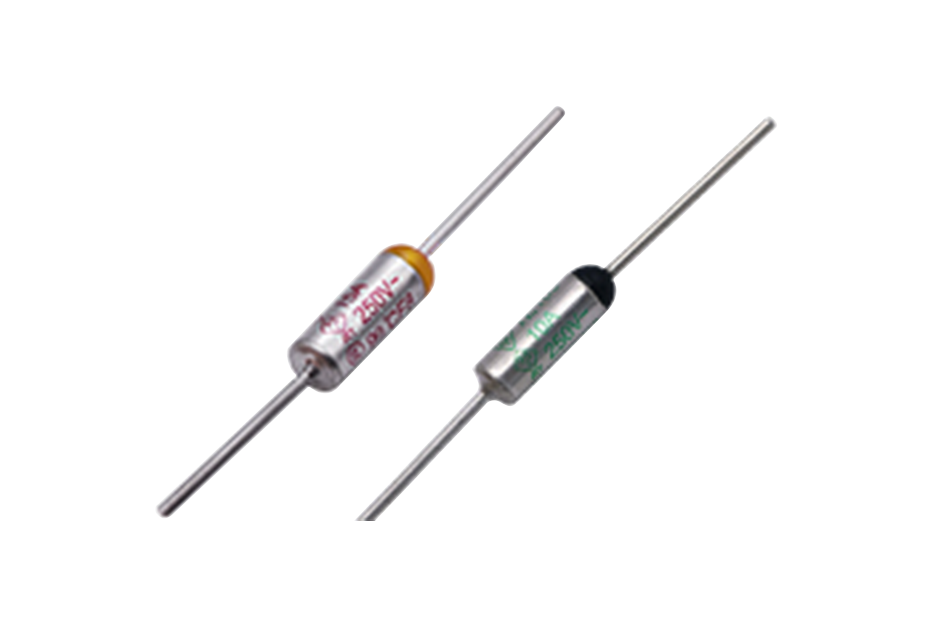

In addition, we also need to consider the working environment of the device. If the device needs to work at extreme ambient temperatures, then we need to choose a fuse with a wider operating temperature range. For the requirements of welding conditions, we also need to choose the right fuse according to the actual welding process.

XC ELECTRONICS glass tube fuse Other considerations

In addition to the above basic parameters and actual needs, we also need to consider some other factors in the selection. For example, whether the size and shape of the fuse meet the installation requirements of the equipment; The price of the fuse is reasonable; As well as the supplier's reputation and service. Although these factors have no direct impact on the performance of the fuse, they will also have a certain impact on actual use and maintenance.