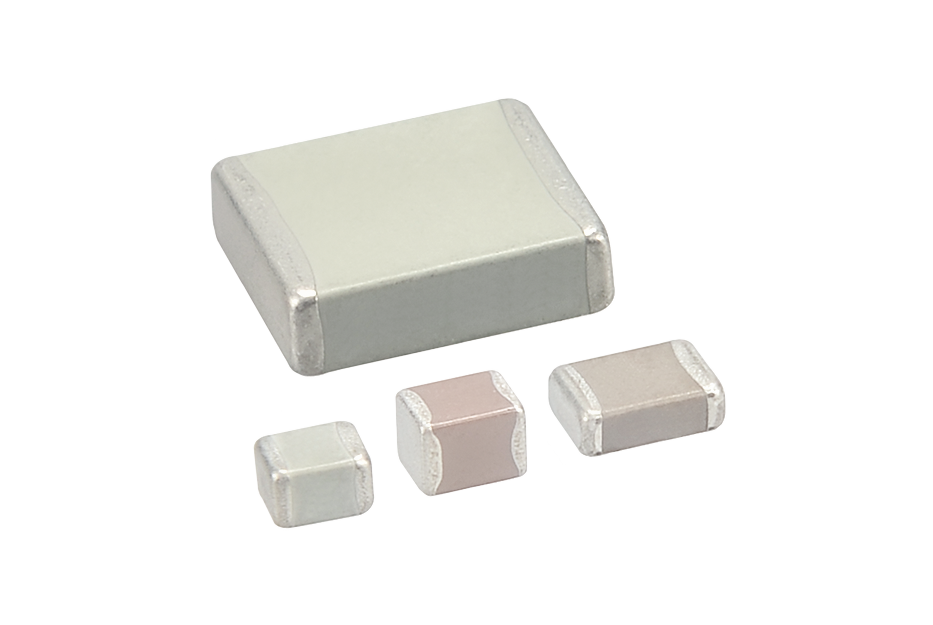

MLCC chip capacitor selection list and online purchase address: click on the image to enter

MLCC is the abbreviation of multilayer Ceramic capacitor, which is a common electronic component. In MLCC, patch capacitors are the most commonly used type. There are many types of materials for chip capacitors, among which Y5V and COG are two common materials. This article will provide a detailed introduction to the differences between Y5V and COG.

Firstly, let's learn about the Y5V material. Y5V is a high dielectric constant material that typically has a high capacitance density. The working temperature range of Y5V material is usually between -30 ℃ and+85 ℃. It has a large capacitance temperature coefficient, typically ranging from -22% to+82%. This means that the capacitance value of Y5V material may vary significantly at different temperatures. In addition, the capacitance stability of Y5V material is poor and is easily affected by the external environment. Therefore, the application of Y5V material chip capacitors in precision electronic equipment is relatively limited.

Secondly, let's learn about COG materials. COG is a low dielectric constant material, also known as NPO material. The working temperature range of COG material is usually between -55 ℃ and+125 ℃, far exceeding the range of Y5V material. The capacitance temperature coefficient of COG material is very small, usually within the range of 0 ± 30ppm/℃. This means that the capacitance value of COG material varies very little at different temperatures and has high stability. In addition, the capacitance value of COG material is almost unaffected by the external environment, and has good moisture resistance and durability. Therefore, COG material chip capacitors are widely used in high-precision electronic devices.

Thirdly, Y5V and COG are two common chip capacitor materials. Y5V material has high dielectric constant, large capacitance temperature coefficient, and poor capacitance stability, making it suitable for some general application scenarios. The COG material has low dielectric constant, very small capacitance temperature coefficient, and good capacitive stability, making it suitable for some application scenarios that require high accuracy.

Fourthly, when choosing the material for SMD capacitors, we need to make the selection based on specific application needs. If working in environments with small temperature changes and high precision requirements for capacitance values, then COG material is a good choice. If working in environments with significant temperature changes and relatively low accuracy requirements for capacitance values, then Y5V material may be more suitable.

In summary, Y5V and COG are two common chip capacitor materials that have significant differences in operating temperature range, capacitance temperature coefficient, and capacitor stability. Choosing appropriate materials is of great significance for the performance and reliability of electronic devices. Therefore, in practical applications, we need to choose appropriate chip capacitor materials based on specific needs to ensure the normal operation of electronic devices.