Selection and purchase address of alloy resistors: click on the image

1. Definition: Alloy resistor is an electronic component made of metal alloy materials, with a certain resistance value and power bearing capacity. It is usually used to adjust the current or realize the function of resistive load in the circuit.

2. Material composition: The main material of alloy resistance is made of metal alloys. Common alloy materials include nickel chromium alloy (such as nickel chromium alloy), nickel chromium iron alloy (such as nickel chromium alloy), nickel chromium molybdenum alloy, etc. These alloys have good electrical resistance characteristics and stability.

3. Characteristics and performance:

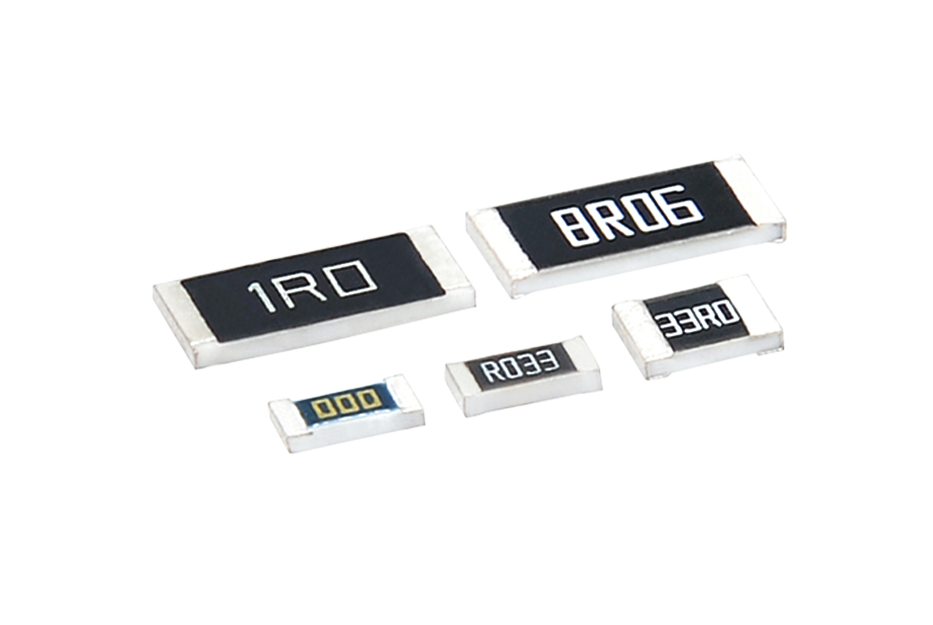

-Resistance range: Alloy resistors provide a wide range of resistance values, ranging from a few ohms to a few megaohms. This makes them suitable for various circuit requirements.

-Temperature coefficient: The temperature coefficient of an alloy resistor represents the degree to which its resistance value changes with temperature. Alloy resistors typically have a lower temperature coefficient, which means they have a smaller response to temperature changes and have better temperature stability.

-Power withstand capacity: Alloy resistors can withstand a certain amount of power, usually marked in watts (W). The power withstand capacity depends on the size, material, and design of the alloy resistor, and an appropriate model can be selected to meet the power requirements of the circuit.

-Accuracy: The accuracy of alloy resistors refers to the difference between their actual resistance value and nominal resistance value. Common accuracy levels include ± 1%, ± 5%, etc. The specific accuracy requirements depend on the application requirements.

-Reliability: The alloy resistor has good stability and reliability, can maintain a stable resistance value in long-term use, and has a low Failure rate.

4. Application field: Alloy resistors have a wide range of applications in various fields, including electronic equipment, communication systems, power management, industrial control, automotive electronics, aerospace, etc. They are used for current limiting, voltage divider, current measurement, temperature compensation, and sensor applications.

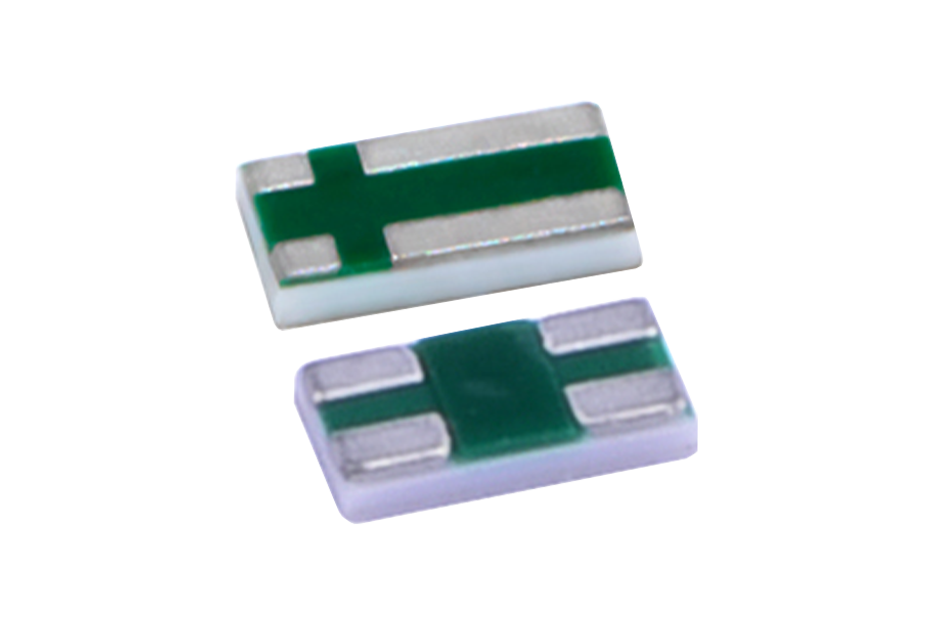

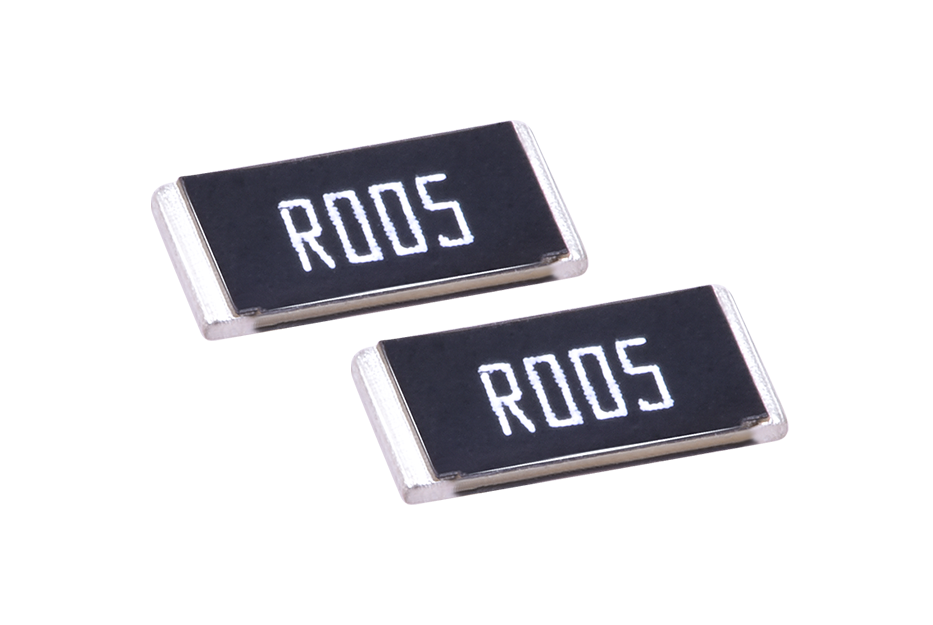

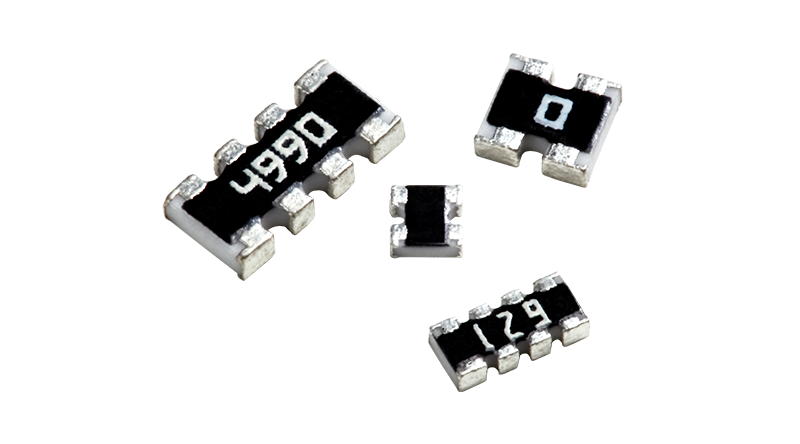

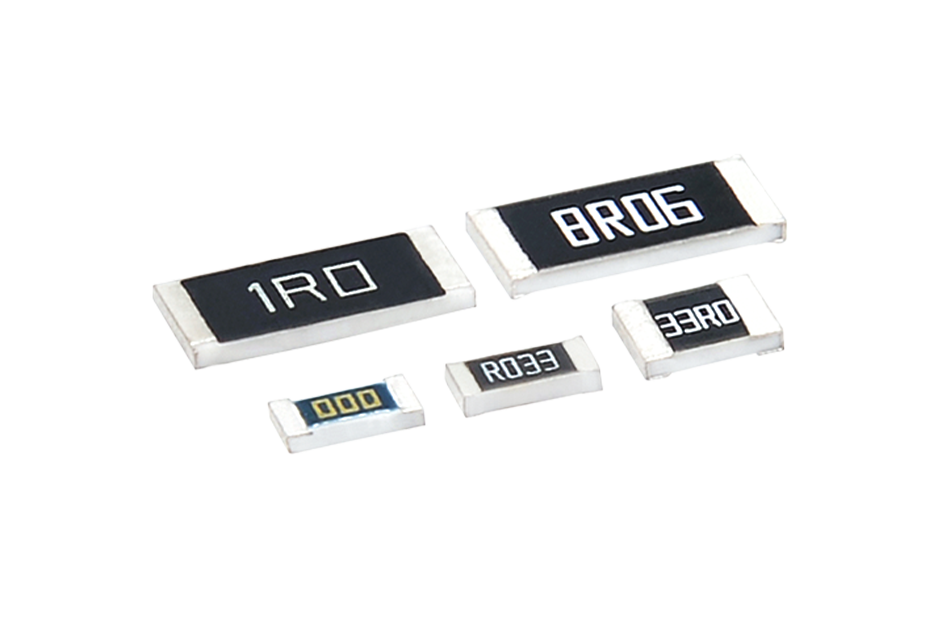

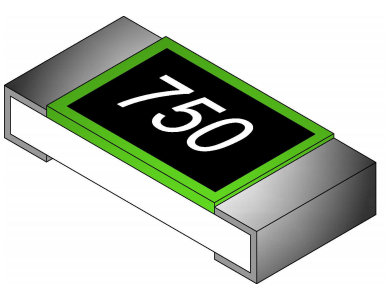

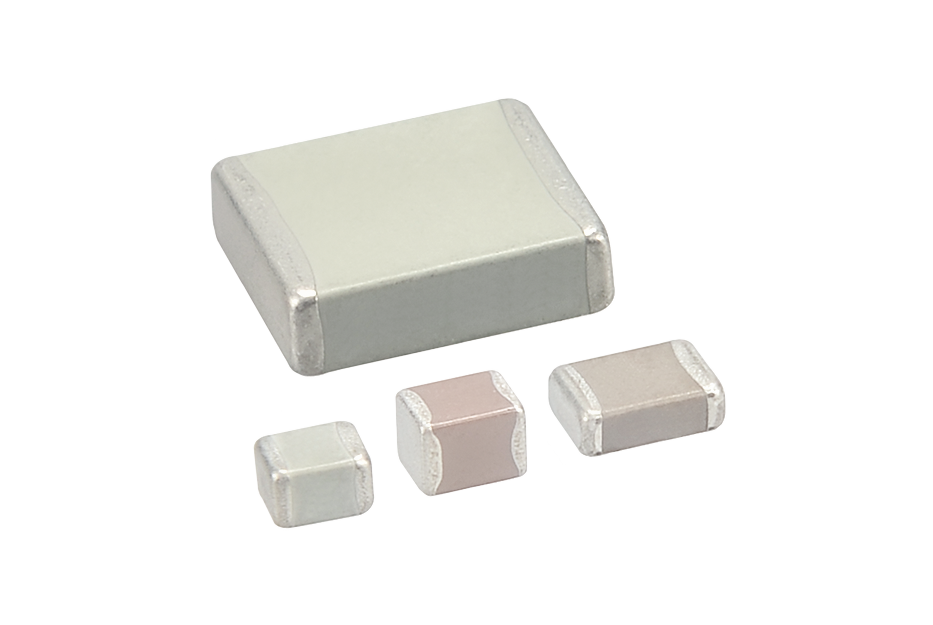

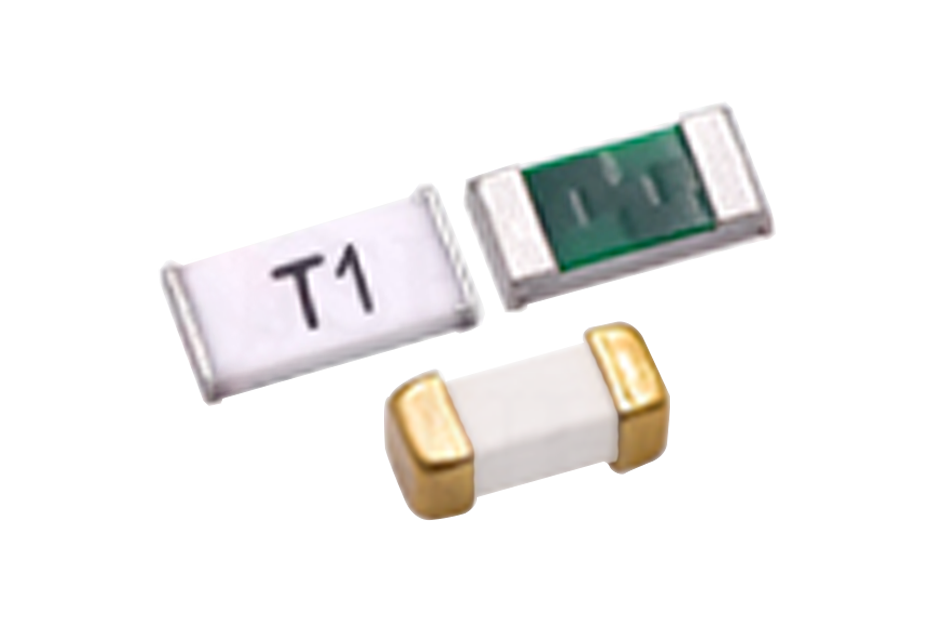

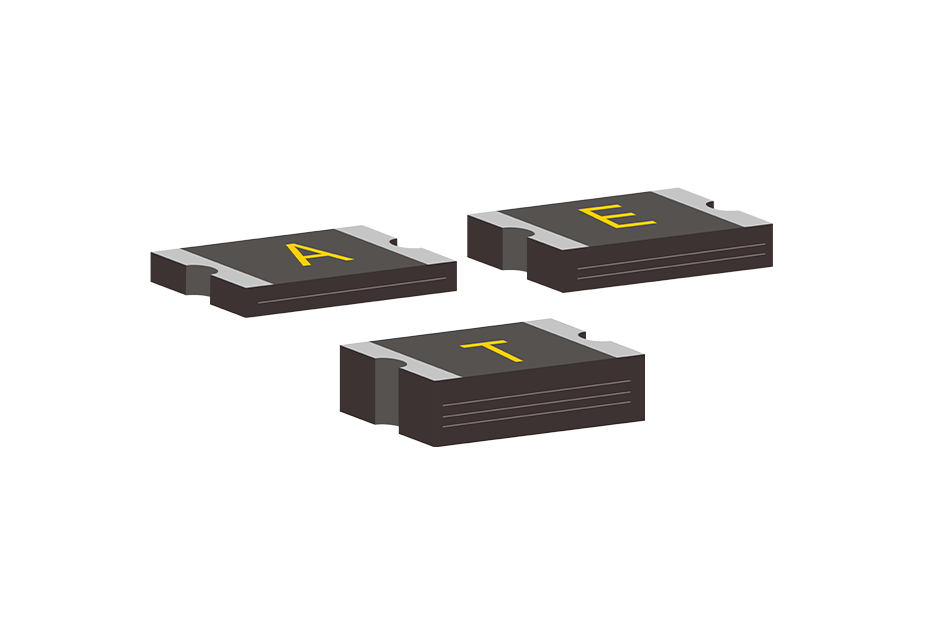

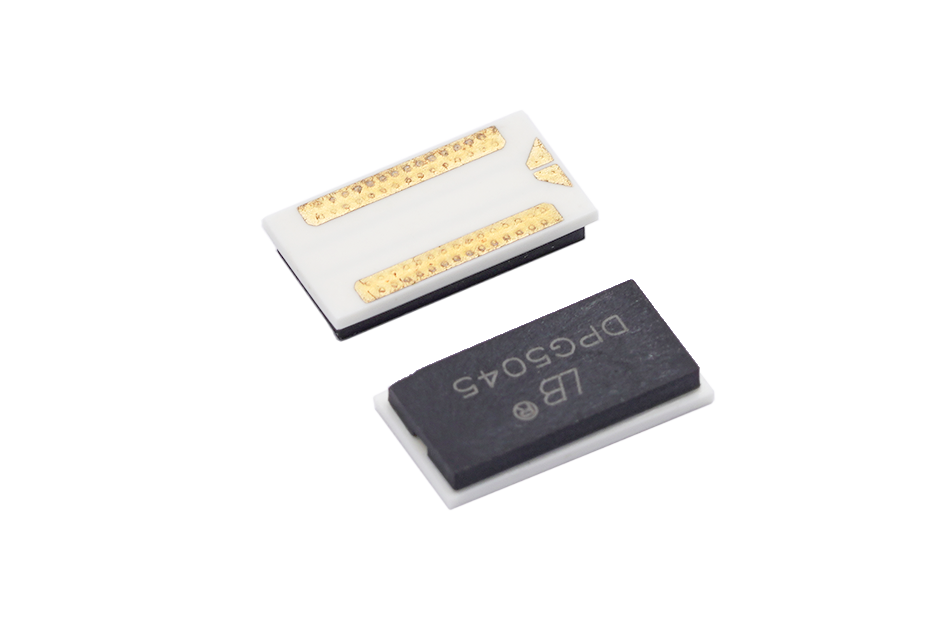

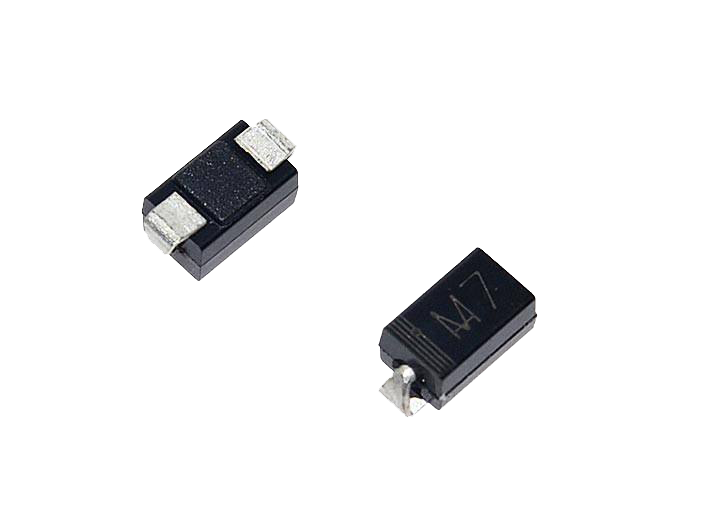

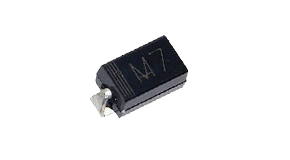

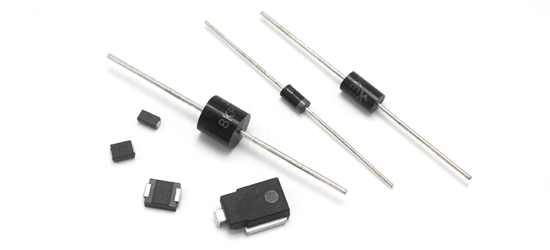

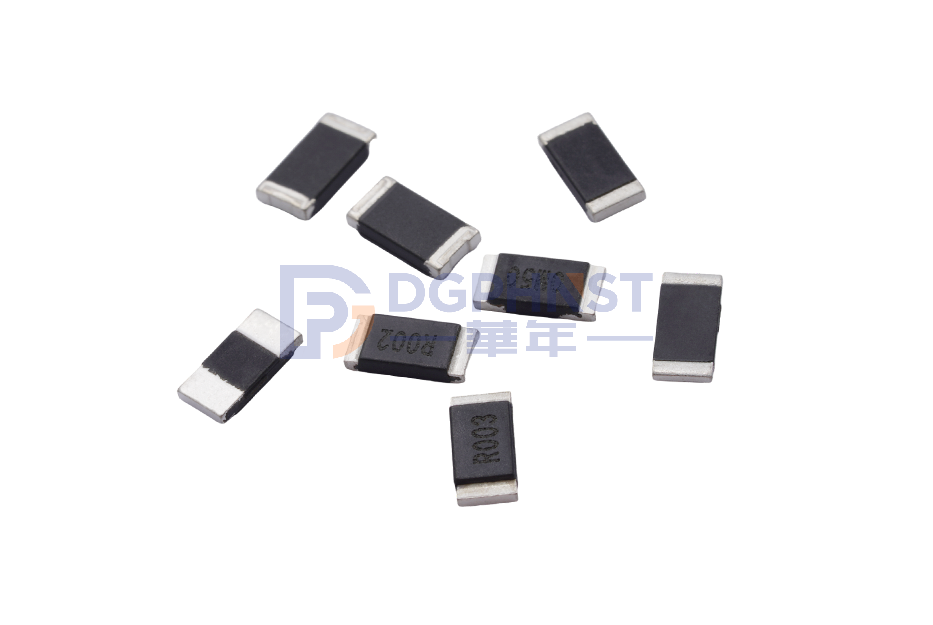

5. Packaging and installation: Alloy resistors are usually provided in the form of chip packaging, chip packaging, or plug-in packaging. Chip packaged alloy resistors are commonly used in surface mount technology (SMT) and can be directly soldered onto circuit boards. SMD packaging usually adopts standard size and packaging type, which is convenient for installation and welding on automated production lines. The alloy resistor encapsulated in the plug-in is suitable for applications that require manual insertion of circuit boards.

6. Identification and coding: Alloy resistors are usually printed with identification and coding to indicate their resistance value, accuracy, power withstand capacity, and other related parameters. Common identification methods include color band encoding, numerical encoding, and label encoding to facilitate user identification and selection of appropriate resistors.

7. Alternatives: In addition to alloy resistors, there are other types of resistors available for similar applications. For example, carbon film resistors, metal film resistors, and metal oxide film resistors are common substitutes. Choosing the appropriate type of resistor depends on the specific application requirements and performance requirements.

In summary, alloy resistors are electronic components made of metal alloy materials, with a wide range of resistance values, good temperature stability, appropriate power tolerance, and reliability. They play an important role in various fields of circuits, meeting the resistance regulation and load requirements of different applications. When selecting, factors such as resistance value, temperature coefficient, power bearing capacity, and accuracy need to be considered, and appropriate packaging and installation forms should be selected based on specific application requirements.