Several countries and regions have begun to introduce carbon pricing mechanisms as a system to transfer greenhouse gas emissions related to business activities to costs. Therefore, decarbonization measures not only have important significance in contributing to society, but also have a significant numerical impact on the business performance report - financial statements.

The decarbonization measures have had a profound impact on the electronics industry, giving rise to an unstoppable new round of semiconductor technology replacement and growth, especially in the field of power semiconductors, replacing traditional silicon-based devices with wide bandgap materials such as silicon carbide (SiC) and gallium nitride (GaN).

In order to reduce greenhouse gas emissions in the future, after half a century, semiconductor materials are facing a comprehensive transformation!

Further reducing power consumption, silicon-based devices encounter bottlenecks

Power semiconductors are semiconductor components that manage, control, and convert the power required for the operation of electrical and electronic equipment. It is embedded in power electronic circuits, which include power supply circuits that provide stable driving power for household appliances and IT equipment, power conversion circuits that transmit and distribute power without waste, and electrical circuits that efficiently drive motors through freely controllable torque and speed.

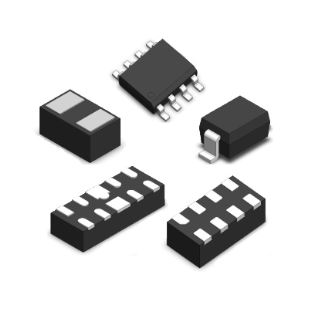

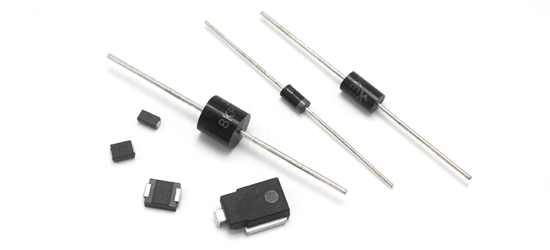

Power semiconductors have various component structures such as MOSFETs, IGBTs, diodes, etc., and are used according to their respective applications. Among them,

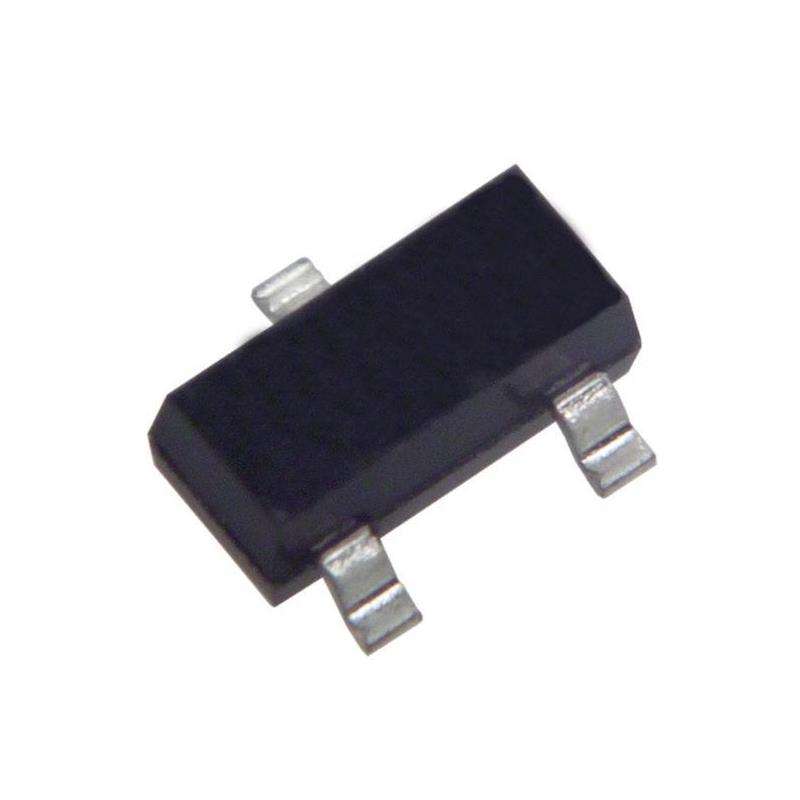

MOSFET (Metal Oxide Semiconductor Field Effect Transformer)

Metal oxide semiconductor field-effect transistor is a type of field-effect transistor that plays an electrical switching role. It consists of three layers: metal, oxide, and semiconductor, which act by applying voltage to an electrode called a gate to turn on and off the current.

IGBT (Insulated Gate Bipolar Transformer)

Insulated gate bipolar transistor is a transistor with a structure that combines MOSFETs and bipolar transistors. Its characteristic is to have both the high-speed operation of MOSFETs and the high voltage resistance and low conduction resistance of bipolar transistors.

Despite its different structures, silicon (Si) has been used as a component material for over half a century. This is because Si has good electrical properties and is easy to process into various component structures.

However, currently Si based power semiconductors are no longer able to meet the high-level technical requirements required to further reduce the power consumption of various electrical and electronic devices. In order to overcome this bottleneck, the range of new materials such as silicon carbide (SiC) and gallium nitride (GaN), which are more suitable as power semiconductor materials than Si, is constantly expanding.

As a key device for achieving sustainable development in society, power semiconductors have undergone a complete pattern transformation after half a century.

SiC and GaN have multiple physical characteristics suitable for power semiconductors, including breakdown electric field strength (which affects voltage endurance), mobility (which affects operating speed), and thermal conductivity (which affects reliability). If we can develop devices that showcase their outstanding characteristics, we can manufacture power semiconductors with higher performance.

Today, SiC based MOSFETs and diodes have been commercialized and used in DC/AC converters for electric vehicle motor drive inverters and solar power generation power regulators.

HEMT (High Electron Mobility Transformer) based on GaN has also been productized. HEMT is a high electron mobility field-effect transistor that can achieve high-speed switching by connecting semiconductors with different properties and inducing high mobility electrons. At present, gallium nitride HEMT has been used in AC converters for ultra small PCs and smartphone chargers.

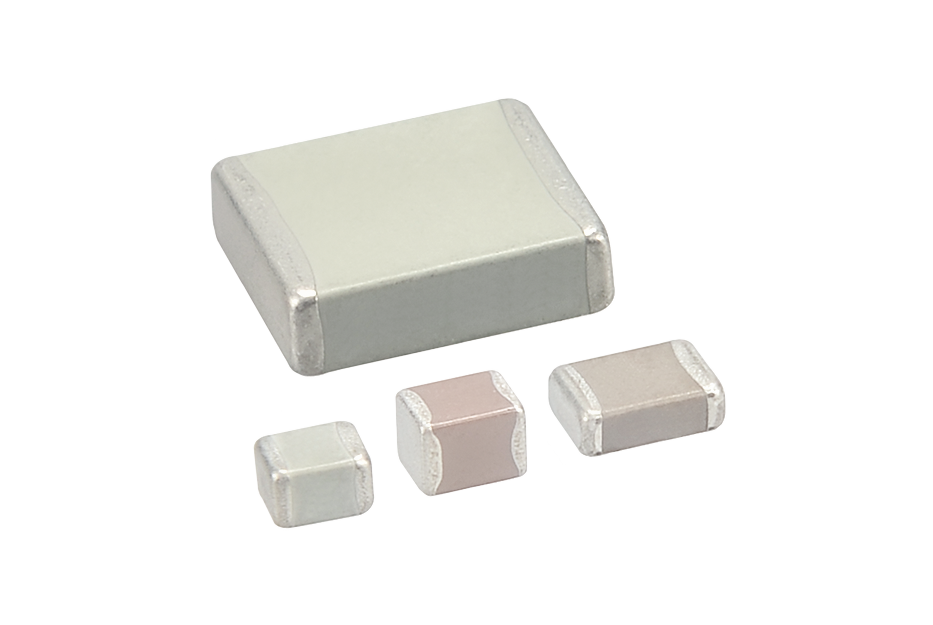

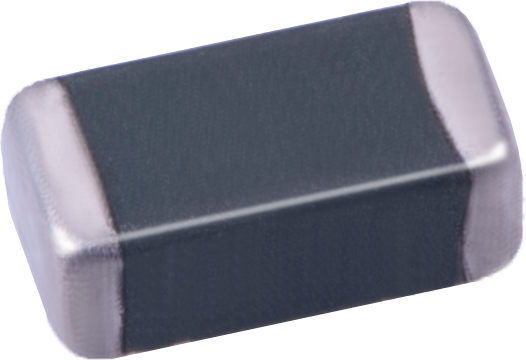

However, to fully unleash the potential of SiC/GaN, the synchronous development of passive components such as capacitors and inductors is essential.

Unleashing the potential of SiC/GaN, passive components are indispensable

Simply replacing Si based components in existing power electronic circuits cannot fully unleash the potential of power semiconductors based on new material manufacturing. This is because other semiconductor ICs, passive components, and even control software that make up power electronic circuits are developed and selected based on the premise of using Si based power semiconductors. In order to effectively utilize power semiconductors based on new materials, these peripheral components also need to be redeveloped and re selected.

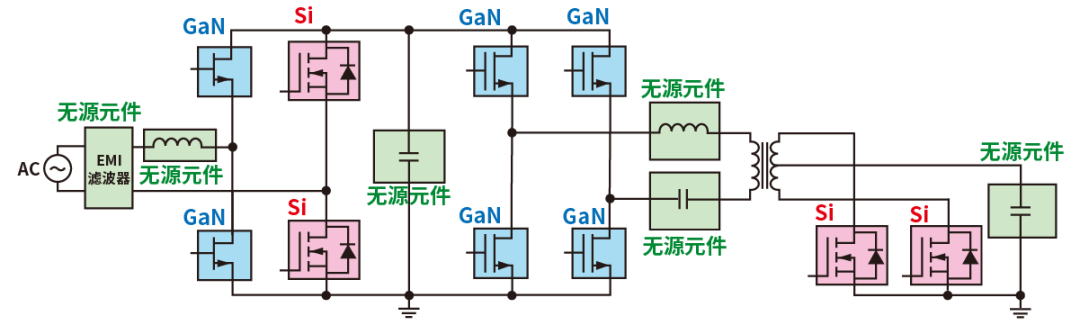

Example of an AC/DC converter using GaN based power semiconductors (for data center servers, etc.) circuit

For example, in the AC/DC converter circuit using GaN HEMT introduced to reduce power consumption of data center servers, multiple GaN HEMTs are used (as shown in the figure above).

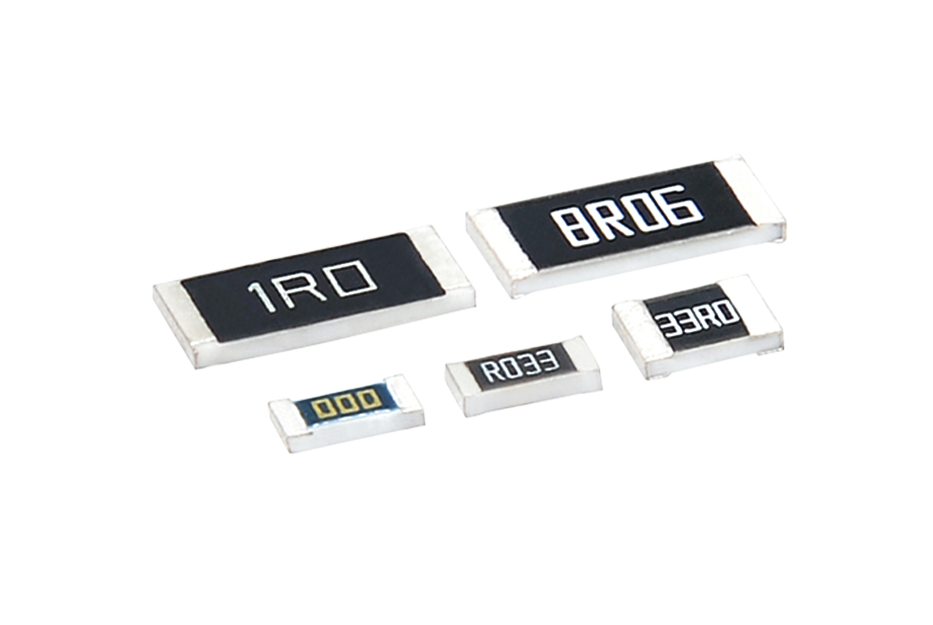

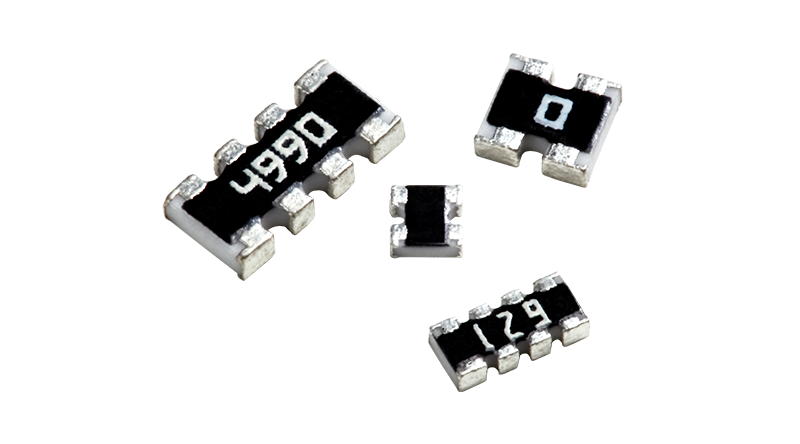

The use of GaN HEMT can achieve high-speed switching at high voltage, which can increase the switching frequency (operating frequency) of power electronic circuits. In circuits with high operating frequencies, the reactance values of the built-in capacitors and inductors in the signal processing circuit can be very small. Generally speaking, low reactance components have smaller dimensions, which can make circuit boards smaller and increase power density. Similarly, in the inverter circuit that drives electric vehicles, SiC MOSFETs can also be introduced to achieve miniaturization of peripheral components, thereby achieving overall miniaturization and lightweighting of the inverter circuit.

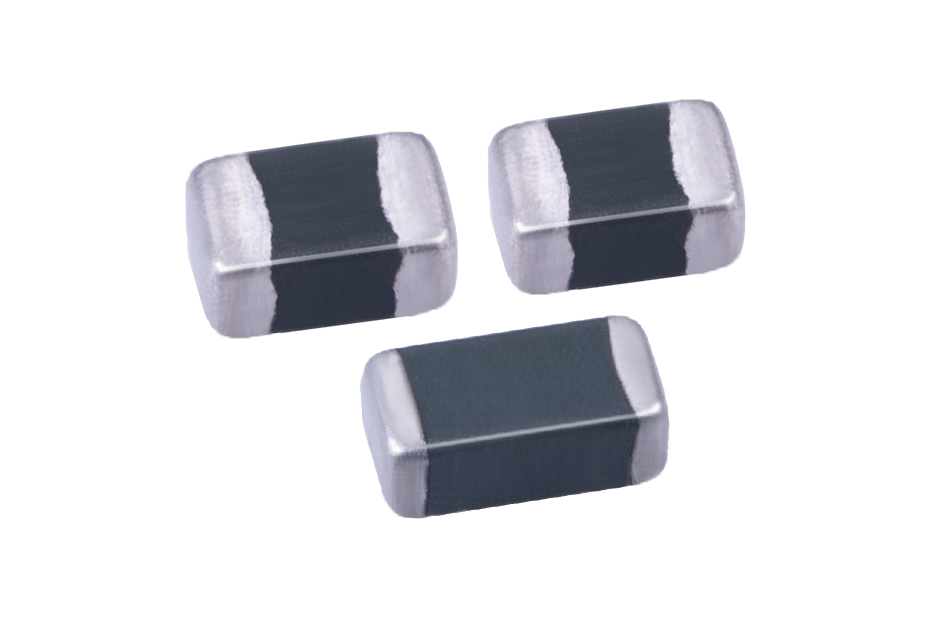

On the other hand, high-speed switching of power supplies at high voltage can generate high-level noise, which may have adverse effects on the operation of surrounding equipment. Power supplies constructed using SiC or GaN power semiconductors switch at higher frequencies, further increasing the risk. Therefore, stricter noise control measures are needed than when using previous power electronic circuits. In this case, it is necessary to use noise cancelling components designed for high voltage, high current, and high-frequency circuits, rather than those used for previous circuits.

In addition, for transformers that are also particularly bulky components in passive components, small transformers that operate at higher frequencies are also required. Thin planar transformers based on SiC and GaN power semiconductors have been developed and put into the market.

Not only focusing on power semiconductors, but also on the progress of peripheral components is equally important!

So far, various types of semiconductors (not just power semiconductors) have been made based on Si. Therefore, many existing electronic components are assumed to be developed in combination with Si based semiconductors. In order to fully leverage the effectiveness of power semiconductors made from new materials, it is not only necessary to search for better components in existing ones, but also to develop new components that meet the requirements of new technologies.

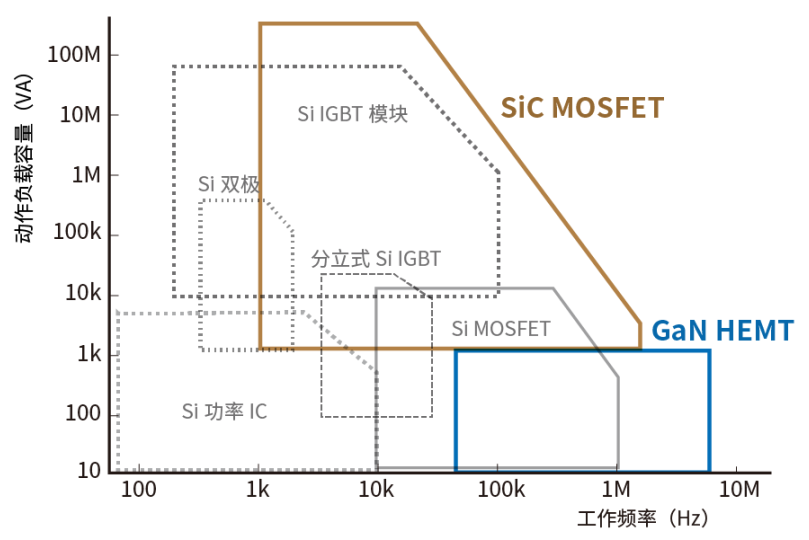

Power semiconductor distribution by component material and structure

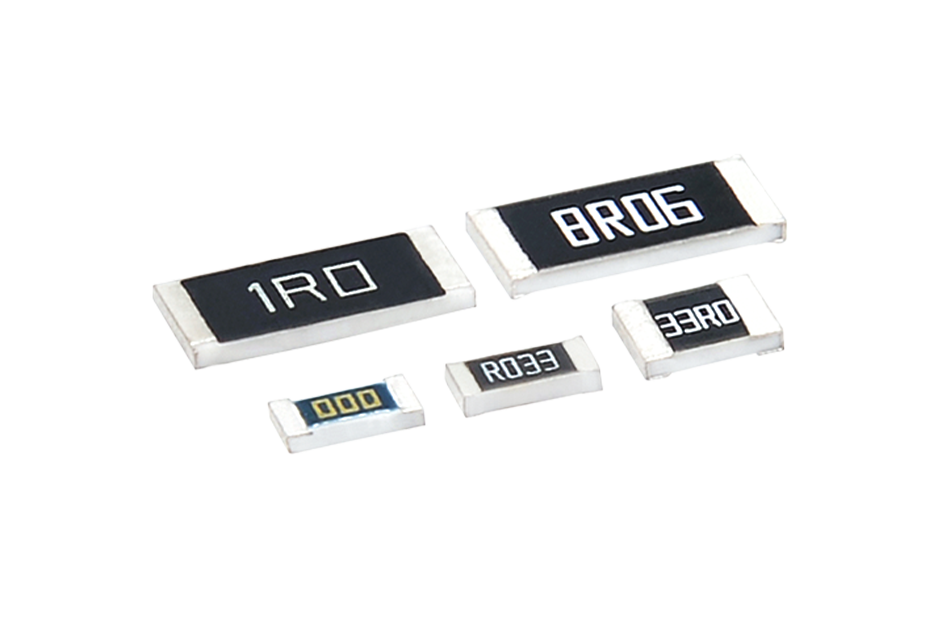

Generally speaking, in Si based power semiconductors, there is a trend towards lower operating speeds of components that can cope with higher voltages and currents (as shown in the above figure). Therefore, small capacitors and reactors that can cope with high voltage and high current are not complete.

In addition, there is a trend to simplify the heat dissipation system in SiC based power semiconductors that can operate stably at high temperatures to reduce size and weight, as well as lower costs. In these cases, passive components also need to ensure high reliability in high-temperature environments.